Honestly, I should not presume to dispense advice on the fine art of building a high performance Tesla coil, when I myself am still making bozo-nono (thanks for the bôn mot Jon!) mistakes such as blowing up capacitors.

Observe:

This is not what a happy, healthy pulse cap looks like, dear readers. This is what a pulse cap looks like after its RMS current rating and frequency rating are exceeded by a few orders of magnitude. Internal solder connections between the individual capacitors in the string melted, then arcs formed, vaporizing the mineral oil impregnant. Technically, the case ought to have a vent to prevent a catastrophic casing rupture, but then technically, I should not have operated the cap in the manner I did.

This was one of two capacitors left over from my days with Dream Park Corporation and DiaboliCo. If I recall correctly, we were paying around $200 each for these. I used one in each ≈1500 watt Tesla coil. They were made to my specs specifically for Tesla coil duty by Plastic Capacitors Inc. They are perfectly fine capacitors, although if you call up PCI and tell them that you want to order a capacitor for a Tesla coil, they might not give you the time of day.

That's because they have lost count of the number of amateur Tesla coil builders who have used their caps, had them fail, and blamed the manufacturer. When DiaboliCo got into the Tesla coil business, PCI were a bit reluctant to talk to me until I started talking quantity, and answered all of their technical questions concerning operating specifications and conditions. As far as I know, not one of the capacitors we sold in any of our Tesla coils (quite a few units, by the way) failed after hundreds of hours of operation. They are good caps if they are specified properly.

As I said above, I ran this cap in conditions far beyond what it was designed for, and it refused to do the impossible. However, the one fun part I got out of all this was what it looks like on the inside, which is the whole reason for this long-winded post.

Incidentally, the ratings on this capacitor were something like (from my notoriously unreliable memory): 0.01µF, 15kVACW (_RMS_ @ 300 kHz) and around 10A circulating current. That last number might be a bit high, it's been over a decade.

I needed two of these for my "Last Tesla Coil" because I have already completed the secondary assembly, which means the designed operating frequency is now fixed. And since I want a large amount of inductance in the primary, that fixes the primary tank capacitance to a very narrow range.

Part of my goal with this coil is to approach the spark-making efficiency (basically, output spark length over input power) of a double-resonant solid state coil -- using a spark gap switched system. It is easy to dissipate half your input power in a badly designed or incorrectly operated spark gap. One way to minimize the power lost in the gap is to minimize the current through the gap. And a great way to do that is to increase the inductance in the primary. Remember, the field intensity generated by the primary goes as ampere * turns, so swapping turns for current doesn't hurt us in terms of transferring energy to the secondary. Also remember that this bloody horrible thing is NOT a transformer, and cannot be modeled as a simple AC transformer. If you knew me 15 years ago, you know that I believed that Tesla coils COULD be modeled as a transformer, albeit a resonant one. Well, I was ignorant. I've learned a few things since then. The point being that we do not care about turns ratio between primary and secondary nearly as much as we would if this were a simple transformer.

So what to do? Well, in the time since I specified and used these capacitors back in the 90s, the state of the art in Tesla coil capacitors improved dramatically, with the development of the "Multiple Miniature Capacitor" -- Capacitor; or "MMC Cap" for short.

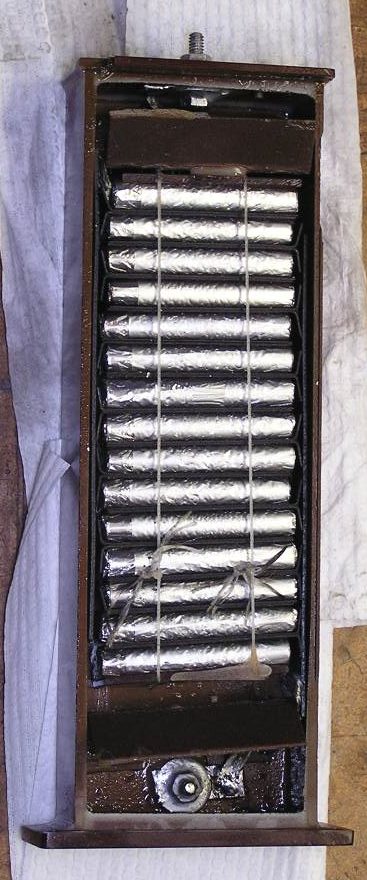

The idea came from a simple logical progression. The Tesla coil building community knew what was inside most high voltage capacitors. Pretty much all of them look like this inside, one way or another, although geometries can change for different purposes. We knew that capacitors that _should_ have withstood some RF voltage and current combination failed anyway, and the cause was widely held to be dielectric losses - the dV/dT was too high for the dielectric.

There were relatively inexpensive "commercial / off the shelf" (COTS) capacitors available with very good dV/dt ratings, but their highest voltage was much too low and so was their capacitance, for any reasonably interesting Tesla coil. They had reasonable tolerance - 10%. So why not string a bunch of them in series to obtain the necessary withstand voltage, and then connect several such strings in parallel to obtain the needed capacitance? How much would that cost?

It turns out that it costs a few hundred dollars at the usual prices to build a large MMC cap. By "large", I mean one capable of running a medium to large sized coil, or in the 1,800 watt to 10 kW range.

The best capacitors, determined by trial and error and a lot of deliberate testing were the 942C series from Cornell Dubilier Electronics (CDE). They were (and remain) damned near unobtainable through regular commercial channels. No one stocks them, not even CDE. Lead times are long. Group buys were put together to bring the price down. An amateur science education and "geek shelter" group made a huge bulk purchase and resold the caps at a reasonable markup (to help support their project) which was still cheaper than most individuals could buy them on their own.

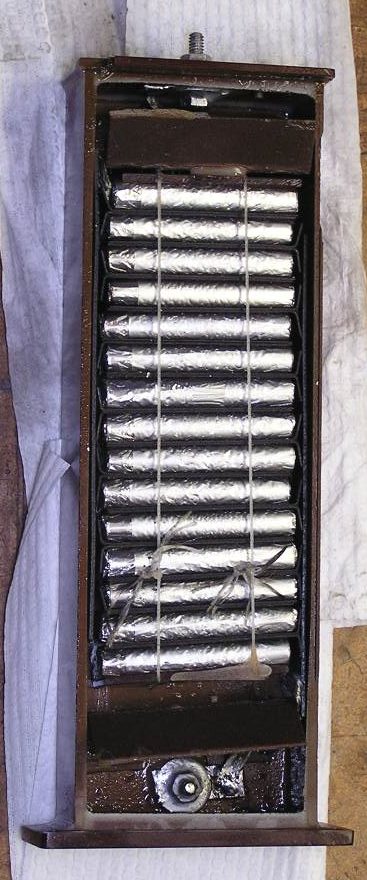

Since then, they've become the defacto standard for anyone who can afford them. They turn up on eBay now and then, which is where I purchased this set:

Conveniently mounted and all connected up for me... except that this unit isn't designed quite conservatively enough to satisfy my fetish for reliability, so I'm going to need a few more. Irrelevant - the price on this lot was very good. I hope I can do as well the next time.

Observe:

This is not what a happy, healthy pulse cap looks like, dear readers. This is what a pulse cap looks like after its RMS current rating and frequency rating are exceeded by a few orders of magnitude. Internal solder connections between the individual capacitors in the string melted, then arcs formed, vaporizing the mineral oil impregnant. Technically, the case ought to have a vent to prevent a catastrophic casing rupture, but then technically, I should not have operated the cap in the manner I did.

This was one of two capacitors left over from my days with Dream Park Corporation and DiaboliCo. If I recall correctly, we were paying around $200 each for these. I used one in each ≈1500 watt Tesla coil. They were made to my specs specifically for Tesla coil duty by Plastic Capacitors Inc. They are perfectly fine capacitors, although if you call up PCI and tell them that you want to order a capacitor for a Tesla coil, they might not give you the time of day.

That's because they have lost count of the number of amateur Tesla coil builders who have used their caps, had them fail, and blamed the manufacturer. When DiaboliCo got into the Tesla coil business, PCI were a bit reluctant to talk to me until I started talking quantity, and answered all of their technical questions concerning operating specifications and conditions. As far as I know, not one of the capacitors we sold in any of our Tesla coils (quite a few units, by the way) failed after hundreds of hours of operation. They are good caps if they are specified properly.

As I said above, I ran this cap in conditions far beyond what it was designed for, and it refused to do the impossible. However, the one fun part I got out of all this was what it looks like on the inside, which is the whole reason for this long-winded post.

Incidentally, the ratings on this capacitor were something like (from my notoriously unreliable memory): 0.01µF, 15kVACW (_RMS_ @ 300 kHz) and around 10A circulating current. That last number might be a bit high, it's been over a decade.

I needed two of these for my "Last Tesla Coil" because I have already completed the secondary assembly, which means the designed operating frequency is now fixed. And since I want a large amount of inductance in the primary, that fixes the primary tank capacitance to a very narrow range.

Part of my goal with this coil is to approach the spark-making efficiency (basically, output spark length over input power) of a double-resonant solid state coil -- using a spark gap switched system. It is easy to dissipate half your input power in a badly designed or incorrectly operated spark gap. One way to minimize the power lost in the gap is to minimize the current through the gap. And a great way to do that is to increase the inductance in the primary. Remember, the field intensity generated by the primary goes as ampere * turns, so swapping turns for current doesn't hurt us in terms of transferring energy to the secondary. Also remember that this bloody horrible thing is NOT a transformer, and cannot be modeled as a simple AC transformer. If you knew me 15 years ago, you know that I believed that Tesla coils COULD be modeled as a transformer, albeit a resonant one. Well, I was ignorant. I've learned a few things since then. The point being that we do not care about turns ratio between primary and secondary nearly as much as we would if this were a simple transformer.

So what to do? Well, in the time since I specified and used these capacitors back in the 90s, the state of the art in Tesla coil capacitors improved dramatically, with the development of the "Multiple Miniature Capacitor" -- Capacitor; or "MMC Cap" for short.

The idea came from a simple logical progression. The Tesla coil building community knew what was inside most high voltage capacitors. Pretty much all of them look like this inside, one way or another, although geometries can change for different purposes. We knew that capacitors that _should_ have withstood some RF voltage and current combination failed anyway, and the cause was widely held to be dielectric losses - the dV/dT was too high for the dielectric.

There were relatively inexpensive "commercial / off the shelf" (COTS) capacitors available with very good dV/dt ratings, but their highest voltage was much too low and so was their capacitance, for any reasonably interesting Tesla coil. They had reasonable tolerance - 10%. So why not string a bunch of them in series to obtain the necessary withstand voltage, and then connect several such strings in parallel to obtain the needed capacitance? How much would that cost?

It turns out that it costs a few hundred dollars at the usual prices to build a large MMC cap. By "large", I mean one capable of running a medium to large sized coil, or in the 1,800 watt to 10 kW range.

The best capacitors, determined by trial and error and a lot of deliberate testing were the 942C series from Cornell Dubilier Electronics (CDE). They were (and remain) damned near unobtainable through regular commercial channels. No one stocks them, not even CDE. Lead times are long. Group buys were put together to bring the price down. An amateur science education and "geek shelter" group made a huge bulk purchase and resold the caps at a reasonable markup (to help support their project) which was still cheaper than most individuals could buy them on their own.

Since then, they've become the defacto standard for anyone who can afford them. They turn up on eBay now and then, which is where I purchased this set:

Conveniently mounted and all connected up for me... except that this unit isn't designed quite conservatively enough to satisfy my fetish for reliability, so I'm going to need a few more. Irrelevant - the price on this lot was very good. I hope I can do as well the next time.

No comments:

Post a Comment