| |

| image ©opyright Zachary Melis |

Built-Up Edge

Q: Why is my surface finish mediocre?

Q: Why is my tool wear excessive?

Q: Why do my carbide inserts keep chipping/cracking/breaking?

A: Built-Up Edge

-

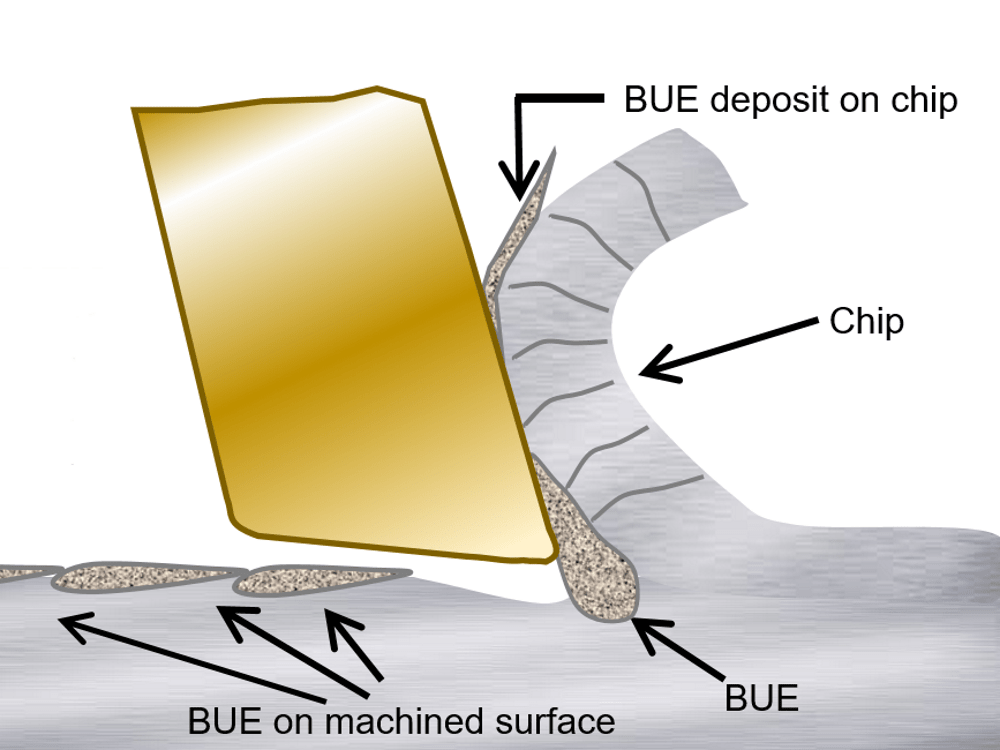

Q: What is Built-Up-Edge?

A: If you have ever drilled aluminum and noticed aluminum piling up on the

cutting edges or tips of your drill bit as if it were a paste and not metal, that is a Built-Up Edge.

BUE happen when removed work material builds up on the rake face of a cutting tool.

-

Q: Why should I care, what harm does BUE cause?

A: BUE impairs surface finish and leads to high cutter wear and early cutter failure.

-

Q: What causes BUE?

A: Any or all of:

1. incorrect cutting speed

2. lack of coolant/lubrication

3. incorrect rake angle or other tool geometry problem (most often rake angle)

4. a dull cutter

5. rough (unpolished) top deck of cutter - AKA the rake surface, where chips or

BUE form

This is an excellent electron micrograph “slo-mo” (a series of stills sequenced

together) of BUE formation:

https://www.youtube.com/watch?v=mRuSYQ5Npek

-

Q: How do I prevent BUE?

A: Not too surprisingly:

1. Use the correct speed & feed for your material and cutter (HSS or carbide).

2. Use a cutting fluid that offers both lubrication and cooling - small amounts are

needed, you donʼt need a system.

3. Use cutters with the correct geometry - generally speaking, the one geometry

that matters most for avoiding BUE is rake angle.

Generally speaking, you will use more positive rake angles (cutting face is tilted

toward workpiece) for softer materials such as aluminum, brass, copper, low

carbon steel, while negative rake (cutting face tilted away from workpiece) is used for harder

materials (tool steel, cast iron), interrupted cuts, or high force applications.

I personally prefer HSS for interrupted cuts.

Positive rake angles create a sharper edge, reducing cutting forces.

Negative rake angles increase cutting edge strength and resistance, make the

edge more durable.

4. Sharpen HSS cutters, rotate or replace carbide inserts, good luck with brazed

carbide - got a diamond tool grinder? Me neither, thatʼs why I use inserts.

5. Polish the top surface of your cutting tool. Be careful, this can dull the edge

and require re-sharpening afterward. WORTH IT.

Coatings (on carbide inserts) can also make a world of difference, but each

coating is specific to one material or family of materials.

So if youʼve got the ubiquitous cheap Chinese inserts with the yellow TiN coating,

youʼll want to know that TiN is an outstanding “non-stick coating” for aluminum

only. It wonʼt help you with ferrous metals, or with cupricmetals, etc.

If you get a coating that does great with one of those, it wonʼt do so well with the other materials.

If you can find the inserts cheap, this is not grossly expensive to deal with, but

when youʼre talking about say, end mills, keeping a set around for three or four

families of metals gets real expensive real fast.

Me not having a money tree, I mostly use high-cobalt HSS cutters with no

coatings at all, and I discourage BUE formation with brushed-on Tap Magic. I know I mention the stuff so often I sound like a get kickbacks from that company but I donʼt, I just like the product best

out of the several most widely-available fluids I have tried over the years.

~≈{👁}≈~

No comments:

Post a Comment