...but only if you care about tool life, surface finish, that sort of thing. ;)

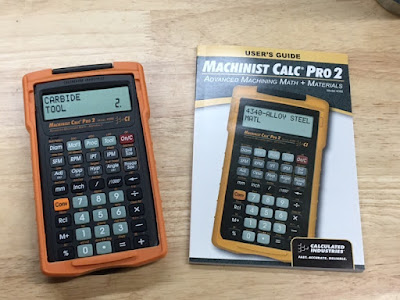

By the way: this calculator was a Christmas gift from my amazing wife. I admit that I put this and other things on my Amazon (I'm sorry) wish list so my better half wouldn't have to wonder whether I'd like the socks she got me. ;)(a little later)

I noticed some things I should report before I forget or get used to them.

0. This is not merely a calculator, it is also a reference book with all the tables you normally would use to make machining calcs manually. As a calculator per se, it can be a little cumbersome. It is also a little clunky to do trig on, which is something machinists do a lot of. I personally have needed trig maybe three times in my life, but I am not a machinist. That said, it does have all the usual trig functions.

This calculator is made for shop floor use. It isn't a scientific calculator and doesn't pretend to be one.

One wag online said about it, "don't make it first year apprentice level" but that's just what it is, and what it should be.

Everything a real machinist learns in their first years, with tables and reams

of paper, stays with them all their working life; this calculator tries to

get rid of the tables and the reams of paper.

If you want something more, get out your scientific one and program it up.

Also, it has an equals key.

[a few gasps are heard from the audience]

Now is when all you RPN fetishists should run screaming into the night, since you won't be able to use this device. :P

|

| I'll be slightly shocked if this doesn't offend someone |

1. What the hell is a "high performance" tool? The calc offers three tool (cutter) materials: HSS, carbide, and "high performance". At first, I assumed it meant ceramic, since that is the only other cutter material I know of. Since I've never been a professional machinist, I figured I'd stumbled over a gap in my knowledge, and I was about to learn something new.

So I searched the web for "high performance" tools and materials in a machining context, and you know what I found out? Not a damned thing. Everyone says their tool / material / cutter geometry is "high performance". The term is not explained in the manual, as if the reader is expected to know. Maybe it's a regional expression; if you're in Europe or Asia, perhaps everyone uses that term.

In any case, since the only tooling I own (er, I think) is either HSS or carbide, I may just ignore it for now. Later I will probably discover or remember that the inserts I use in my lathe tools, and the inserts for my 3" shell mill, are all ceramic, I dunno. I wonder how I would even tell! ¯\_(ツ)_/¯

2. My experience with calculators that run on coin cells dictates that this MF - which uses one cell not two - is gonna eat batteries like mad. I'll be delighted to be proved wrong if it happens.

(spiffs)

• At any time during any calculation, you can switch between the inch and metric systems without re-entering anything, as should be.

• Fractions are entered (and any number in the display or memory) can be flipped between fractional and decimal display simply by hitting the slash key. Can you remember the decimal equivalent for a 17/64 drill? I sure as hell can't. This changes nothing in memory, so switching what is displayed, or using it to enter a number, will not change how calculations are performed on that number.

• It has more functions than most individual professional machinists

will use, but different professionals will use different function sets.

While reviewing opinions on Home Shop Machinist (which, unfortunately,

is populated by a disproportionate number of grumpy, snarky,

condescending pros and retired pros lording themselves over the few amateurs so foolish as to ask questions) I found some singing the praises of one feature set (thread

measuring for example - I will never own or use a 3-wire measuring kit

ever, but YMMV) whilst others poo-poo'd that feature and praised

something else.

Your computer can do more things than you will ever use it for too. Relax and enjoy it.

~≈{👁}≈~

No comments:

Post a Comment